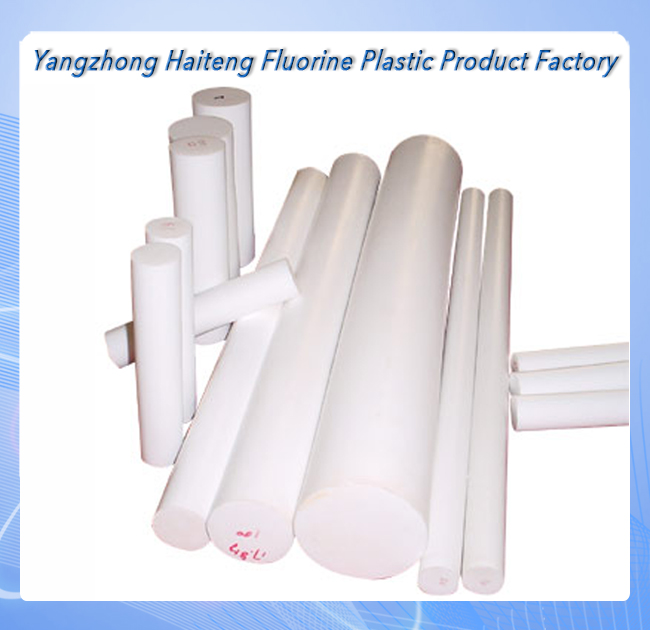

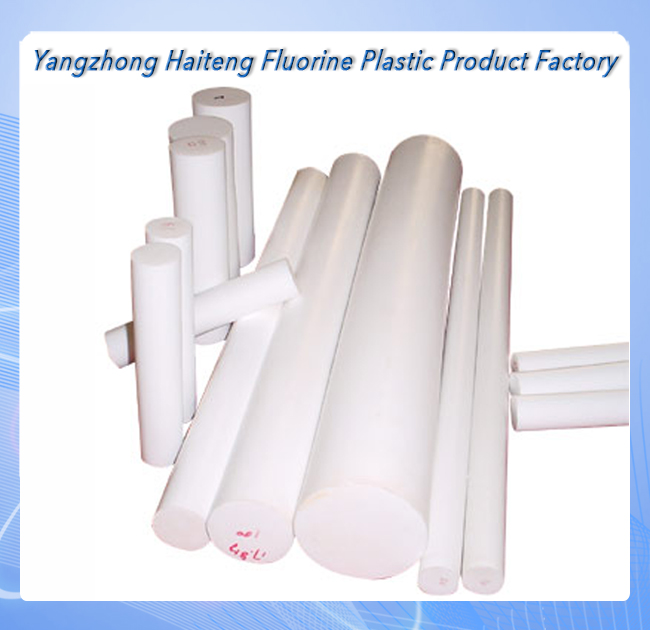

Extruded PTFE Teflon Rod For Aerospace Industry

Specifications:

-Extruded Rod:

Min Diameter= 2mm, Max Diameter= 150mm, Length= normal 1 m, or according to customer's request

-Molded Rod:

Min Diameter= 5mm, Max Diameter=300mm, Length: Max= 300mm

Features:

1.Usage temperature range is very broad (-180°C--+260°C).

2. Anti-majority chemical substance's corrosiveness, except some fluorides and alkalinity molten metal.

3. Excellent mechanical properties, aging resistance.

4. Excellent flame resistance(Conforms to ASTM-D635 and D470 test step),in the air to be regulated as a flame retardant material.

5. Very low water absorption.

6. Has the self lubrication and not the coherency.

7. Excellent insulation characteristic (Regardless of its frequency and temperature how).

Applications:

1, For low friction bearings, bushers, rollers and pulleys.

2, Used in cryogenic components due to its ultra low operating temperatures.

3, The most important engineering plastic used within the aerospace industry and aeronautics

4, Food industry companies.

5, Sealing products.

Advantages:

1, Low co-efficient of friction---- To reduce load and drag in bearings to improve efficiency and reduce frictional

2, compression----conform to mating components resulting in excellent sealing capacity.

3, resistant to most acids----To be used in aggressive environments

Images:

PTFE resin,filled with some filling stuff,can prolong the life of products and

strengthen the performance,eg:Graphite,Carbon ,Glass fiber ,bronze

| Glass Fiber: | Increases compressive strength, rigidity and wear.

Reduces creep and cold flow

Minimal effect on chemical and electrical properties |

| Carbon: | Increases compressive strength, hardness, wear, and load properties.

Good chemical resistance

Various types and amounts of carbon can be added to alter conductivity |

| Graphite: | Reduces coefficient of friction

Reduces initial wear

Increases strength |

| Molybdenum Disulfide: | Increases hardness, stiffness, and wear

Minimal effect on chemical and electrical properties |

| Bronze: | Increases hardness and wear resistance

Increases dimensional stability and compressive strength

Not suitable for corrosive or electrical applications |

Product Categories : PTFE Products > PTFE Rod